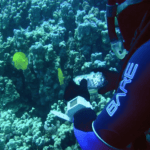

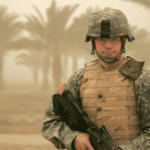

When your device is deployed in the middle of nowhere – underwater, on a remote bridge, or deep in the desert – you don’t get a second chance to pick the right power source.

In the world of remote wireless devices, time isn’t just money—it’s reliability, performance, and in many cases, years of valuable data. The wrong battery can lead to operational failure, safety risks, and significant replacement costs.

So how do you choose a battery you can trust, when everything depends on it?

Step One: Know What Your Device Needs

Remote IIoT devices typically spend most of their time in sleep mode, waking up occasionally to transmit data or check status. That means they need:

- Ultra-low average current (in microamps)

- Short, high-energy pulses (in amps) for wireless communication

Choosing the right battery depends on this balance. Primary (non-rechargeable) lithium batteries are ideal for low-power, long-life applications. Rechargeable batteries with energy harvesting are better suited for high-drain systems.

Not All Batteries Are Built the Same

Alkaline batteries are cheap and common—but they self-discharge rapidly (up to 60% per year), don’t handle extreme temperatures well, and have low energy density. They’re great for flashlights, but not for seismic sensors sitting at the bottom of the ocean.

Bobbin-type lithium thionyl chloride (LiSOCl₂) batteries are the gold standard for extreme industrial conditions:

- Up to a 40-year lifespan

- Temperature range: –80°C to +125°C

- High energy density and voltage

- Self-discharge as low as 0.7% per year

That translates to fewer replacements, lower long-term costs, and better ROI.

Heat, Cold, and the Harsh Reality

Environmental conditions play a massive role in battery life. Extreme cold can slow down chemical reactions, while excessive heat speeds them up—leading to faster self-discharge, voltage drops, and even failure under load.

The Secret Weapon: Passivation

Bobbin-type LiSOCl₂ batteries benefit from a natural phenomenon called passivation—a thin layer of lithium chloride forms on the anode and reduces self-discharge when the battery is idle. This layer temporarily resists current flow when reactivated but quickly dissipates during use.

It’s a delicate balance – too much passivation and your device stalls. That’s why quality manufacturing is key.

Wireless? Don’t Forget the Pulse

Devices with two-way wireless communication can require pulse currents of up to 15A. That’s far more than a typical battery can handle alone. The solution? A Hybrid Layer Capacitor (HLC) that works alongside the battery—delivering intense, short bursts of energy without draining the primary power source.

Do Your Homework

Short-term battery tests won’t reveal how a cell performs over decades. You need to:

- Demand third-party documentation and test reports

- Compare real-world data from similar applications

- Investigate long-term performance, not just specs on paper

Some brands claim “40-year life” but have self-discharge rates too high to support it. That’s why rigorous testing – and experience – matter.

The Bottom Line

When battery replacement isn’t an option, your battery choice becomes mission-critical. Sometimes the cheapest option turns out to be the most expensive.

Not sure which battery fits your application? Let’s talk. Reach out today to speak with one of our experienced applications engineers, who will help you choose the most reliable and cost-effective power solution for your unique needs.